Sharplex have supplied several filters for Molten Sulphur Filtration in sulphuric acid & sulphonation plants.

Normally ‘ASH’ is a impurity which needs to be removed from sulphur so that further processing using molten sulphur should be smooth.

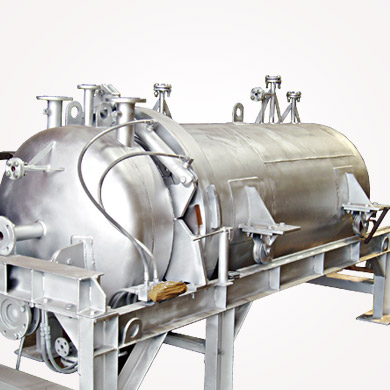

Sharplex offers horizontal pressure leaf filter for molten sulphur filtration in two versions i.e.

- Shell retraction design –

- Bundle retraction design –

In shell retraction design leaf remains steady and shell is retracted to & fro.

In bundle Retraction Design Shell is steady and leaf bundle is retracted to and fro.

Both the versions are operated for opening and closing of filter Hydrulically for easy of operation.

General Process

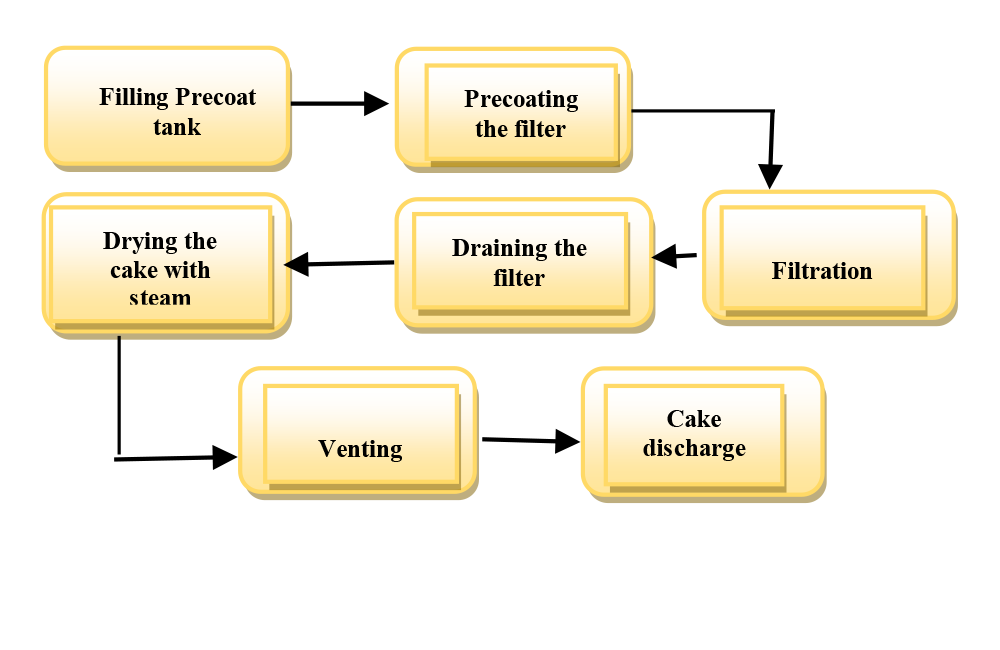

Initially the filter is precoated with filteraid (kieselguhr or perlite). After precoating molten sulphur from sulphur pits is fed to the filter for filtration of ash. After the filtration cake is dried with steam. After drying is complete filter is opened and cake is removed manually by knocking at leaf bottom by wooden spatula

Typical Filtration Cycle

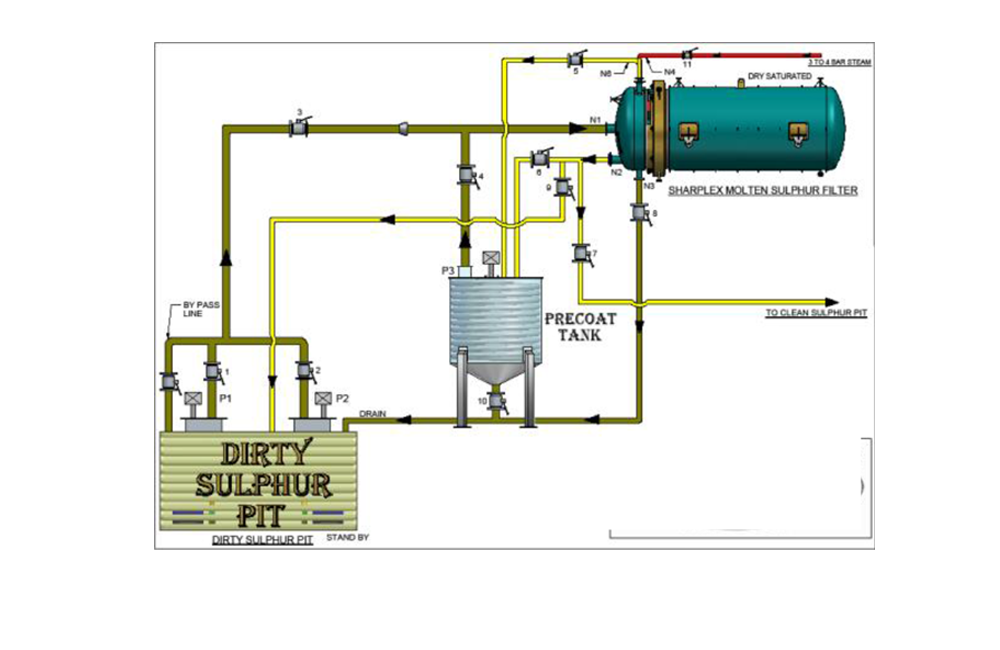

Process Flow Sheet

Material

Normally filter vessel is manufactured in carbon steel / boiler quality material and is jacketed. Filter leafs are made of 5 layer design and in complete stainless steel. Leafs are bolted or rivetted design.

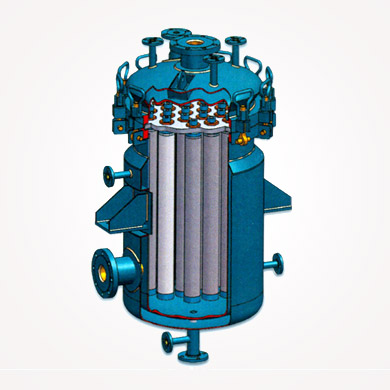

Cartridge Filters for Sulphur Polishing

Cartridge type polishing filters are installed after main molten sulphur filters to remove traces of fine suspended particles of ash and filteraids escaped from main filter, which may choke the downstream equipments in the plant

The removal of these fine solids will help in running the downstream equipments smooth without interruptions. this will result in reducing the downtime of the plant to great extent.